Microfluidics, a field that manipulates and controls fluids on the microscale, has increasingly become a crucial tool in areas like lab-on-a-chip technology, biomolecular analysis, and drug delivery. This technology works in conjunction with microwave sensors, devices that detect and measure the properties of a material or system using microwave radiation. They play a significant role in real-time sensing and monitoring, including applications in food quality control, environmental monitoring, and biomedical diagnostics. On the other hand, additive manufacturing (AM), such as 3D printing, is a process where material is added layer by layer to create a product whereas subtractive manufacturing (SM), conversely, involves removing material from a solid block to create the desired product and is widely utilised in industries such as healthcare, aerospace, and electronics.

First Design

In this project, two microfluidic integrated microwave sensor designs have been proposed and evaluated. The first one is based on a scientific paper and is built using a dielectric material called F4B and copper. Its operating frequency is 11 GHz, and uses spoof surface plasmon polaritons waveguide to detect a sample’s refractive index. The second one is designed from scratch and uses an all-dielectric material called HTM140, and operates at 300-330 GHz, depending on the material selected for the sample. It has a microfluidic channel that can take 0.27 µL of liquids, and is designed to characterise different concentrations of NaCl solutions.

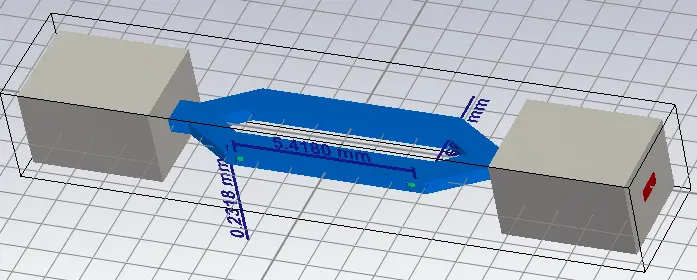

Second Design

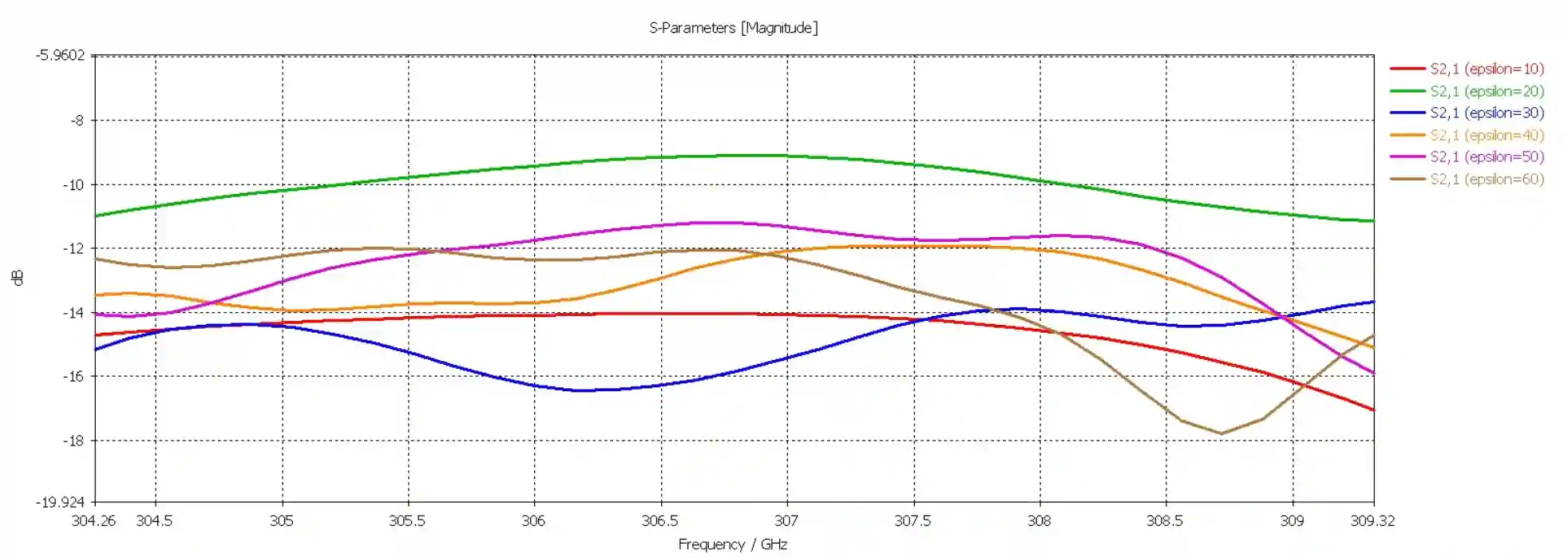

Based on simulations, the second design is able to differentiate NaCl solutions with epsilons (dielectric constants) ranging from 10 - 60. This is likely to be able to distinguish NaCl solutions from 1%-20% concentration at 300 GHz. Further experiments will still need to be made to validate these results, as there is no prior research on how NaCl solutions will react at such high frequencies. There are many advantages to such a sensor. It has a small size effective at sensing microliter liquid volume, has an easy design and fabrication thanks to AM and SM techniques, and facilitates noninvasive and contactless measurements. These advantages are applicable in field such as medical technologies, where remote sensing for NaCl and glucose concentrations can make use of these useful features.

Simulation Result